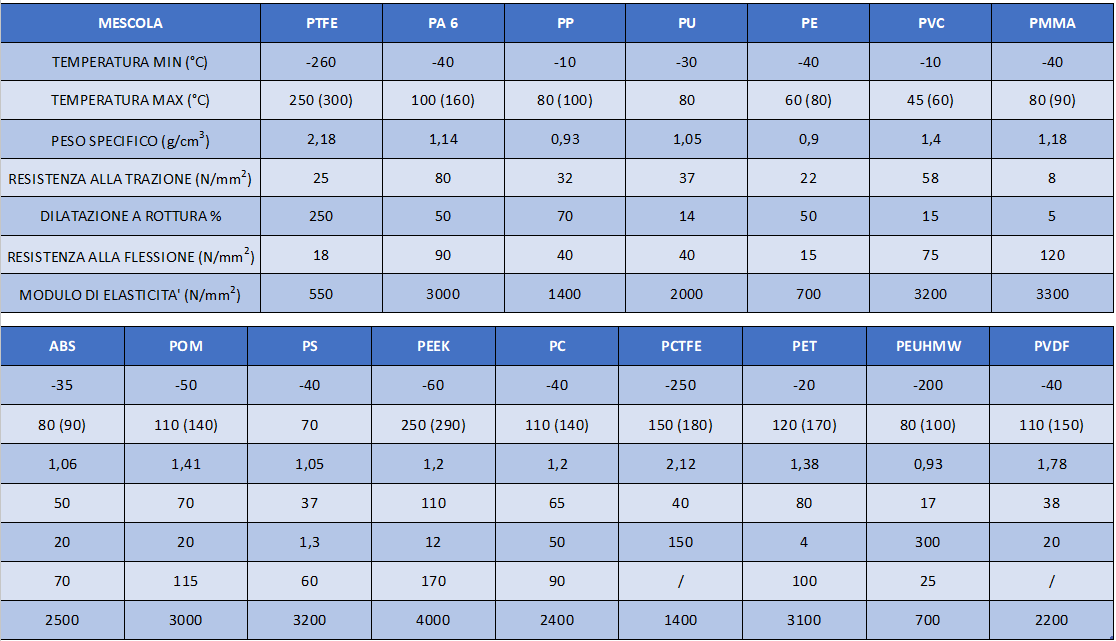

MB Gaskets is able to process different types of plastic materials.

These polymers, characterised by long molecular chains, are divided into three categories: thermosets, thermoplastics and elastomers.

The main thermosets that MB Gaskets processes are " PU (Polyurethane) ".

For elastomers we refer to the RUBBER section.

Main thermoplastics processed are:

PA 6 (Nylon)

This technopolymer has a high mechanical resistance to abrasion...

PP (Polipropilene)

This material is a semi-crystalline polyethylene-like...

PE (Polietilene)

This semi-crystalline has excellent resistance to chemicals...

PVC

This thermoplastic with an amorphous structure has a variety of uses...

PMMA

This plastic material consists of polymers of methyl methacrylate...

ABS

This amorphous thermoplastic resin is obtained from acronitrile...

POM

This thermoplastic has a crystalline structure in which a methylene group alternates with an oxygen atom...

PS

This thermoplastic is one of the oldest. It is similar to PVC, has a very clean surface and high quality...

PEEK

This semi-crystalline thermoplastic is very expensive, but guarantees high performance...

PC

This amorphous material is very tough, rigid, resistant and extraordinarily transparent...

PCTFE

This polymer is very similar to PTFE, but in the base monomer a chlorine atom replaces a fluorine atom, generating irregularities...

PET

This semi-crystalline thermoplastic has high dimensional stability and is therefore used for high-precision parts...

PVDF

This semi-crystalline polymer is partially fluorinated...

Specialising in industrial seals

Pre- and after-sales advice and assistance

Customer request

We carefully evaluate each of our customers' requests in order to offer customised, quality solutions.

Technical consultancy

Proven experience in various manufacturing sectors: mechanical engineering, automotive, hydraulics, petroleum and pharmaceuticals. We offer tailor-made solutions, guaranteeing high quality and customer satisfaction.

Production

Our production includes both standard and customised production, even with special compounds. we produce customised seals based on customer drawings within a short time frame.

Logistics and Warehouse

Timeliness of delivery thanks to a large warehouse that enables rapid dispatch and delivery.

Customisation

we offer customised labels to give your products a unique touch. We are here to provide you with a customised service that perfectly suits your business needs.

PA6 (Nylon)

This polymer possesses high chemical resistance and high chemical stability against thermal excitation, in fact, its characteristics remain suitable up to temperatures of 260°C. In addition, it has excellent anti-adhesive properties, a low abrasion coefficient, high dimensional stability and extreme resistance to ageing with the ability to retain elasticity over time.

PP (Polipropilene)

This material is a semi-crystalline material similar to polyethylene but with greater rigidity and resistance to higher temperatures. It has good chemical resistance in particular to acids and alkalis. Unlike engineering polymers, it has poorer mechanical properties such as tensile strength, flexural strength, abrasion resistance and impact resistance.

PE (Polietilene)

This semi-crystalline has excellent resistance to chemicals. It is resistant to water, salt solutions, acids, alkalis, alcohol and petrol.

It offers excellent impact and abrasion resistance and possesses a high degree of viscosity. However, it is incompatible with oxidising acids such as nitric acid, sulphuric acid and halogens. It can be used for food purposes as it is non-toxic and absorbs very little water.

Polyethylene can also be presented as:

- E-HD (High Density Polyethylene)

- PE-HMW (High-Molecular-Weight Polyethylene)

- PE-UHMW (Ultra High Molecular Weight Polyethylene)

PVC

This thermoplastic with an amorphous structure has many possible uses. It has good chemical stability and in particular is resistant to acids. It is self-extinguishing, absorbs little water and is a good electrical insulator. It also has excellent stability and a high modulus of elasticity. It has good mechanical properties. It does not, however, withstand high temperatures.

PMMA (Plexiglass or polymethyl methacrylate)

This plastic material is formed from polymers of methyl methacrylate.

It is rigid and transparent and can often replace glass due to its incredible light transmission capabilities.

It resists chemicals and weathering well and is suitable for food contact. It has a high modulus of elasticity although it is not very tensile resistant. It is, however, very resistant to bending.

ABS (Acrylonitrile butadiene styrene)

This amorphous thermoplastic resin is obtained from acronitrile, butadiene and styrene by copolymerisation.

It has good resistance to acids, alkalis, alcohols and oils, but not to chlorinated, nitric and sulphuric acids. It has high impact resistance, has good flow properties, and is very tough. It has poor weathering resistance and is therefore mainly used for indoor applications.

POM (acetal resin or Delrin)

This thermoplastic has a crystalline structure in which a methylene group alternates with an oxygen atom. This provides high stiffness, good wear resistance and resilience. It allows low dimensional tolerances.

It is non-toxic and absorbs little water. It withstands quite high temperatures, but has low compatibility with chemicals.

PS (polystyrene or compact polystyrene)

This thermoplastic is one of the oldest. It is similar to PVC, has a very clean surface and high quality. It is very resistant even at low temperatures. It is compatible with foodstuffs. It has excellent electrical insulation properties.

PEEK (Polietereterchetone)

This semi-crystalline thermoplastic is very expensive, but guarantees high performance at both very high temperatures (over 250 C°) and very low temperatures (-60 C°).

It has excellent mechanical properties such as stiffness and hardness, high resistance to wear, abrasion, bending and tensile stress, and very good dimensional stability.

It has excellent chemical resistance, is hardly flammable and is also self-extinguishing.

POM (acetal resin or Delrin)

This thermoplastic has a crystalline structure in which a methylene group alternates with an oxygen atom. This provides high stiffness, good wear resistance and resilience. It allows low dimensional tolerances.

It is non-toxic and absorbs little water. It withstands quite high temperatures, but has low compatibility with chemicals.

PC (Polycarbonate)

This amorphous material is very tough, rigid, resistant and extraordinarily transparent, which is why it is often used instead of glass also because it is very resistant to external weathering. It has excellent electrical properties and is a good thermal insulator, resisting heat.

It has high mechanical resistance to impact, good workability, it is also cold bendable, and good chemical and physical stability.

PCTFE (Polychlorotrifluoroethylene)

This polymer is very similar to PTFE, but in the base monomer, a chlorine atom replaces a fluorine atom, creating irregularities. It has good chemical resistance, excellent water impermeability and a low coefficient of friction.

Compared to Teflon, it is more easily workable with better flexibility and tensile strength. It withstands very low temperatures, while it has a lower resistance to high temperatures than PTFE.

PET (Polyethylene terephthalate)

This semi-crystalline thermoplastic has high dimensional stability and is therefore used for high-precision parts. This is mainly due to the fact that it is particularly insensitive to moisture.

It has a low coefficient of friction, has good mechanical strength, rigidity and hardness, and is wear-resistant. It is a good electrical insulator and fairly resistant to acids.

PVDF (Polyvinylidenefluoride)

This semi-crystalline polymer is partially fluorinated. It has excellent chemical resistance characteristics, especially to acids, and mechanical resistance.

It has a low coefficient of friction and is resistant to weathering, ageing and wear. It is a good electrical insulator. It has low flammability. It is very pure and non-toxic, so it can be used for food purposes.

Richiedi Informazioni